Wing Walls Fortify Stream Crossing for a Resilient Bridge Solution

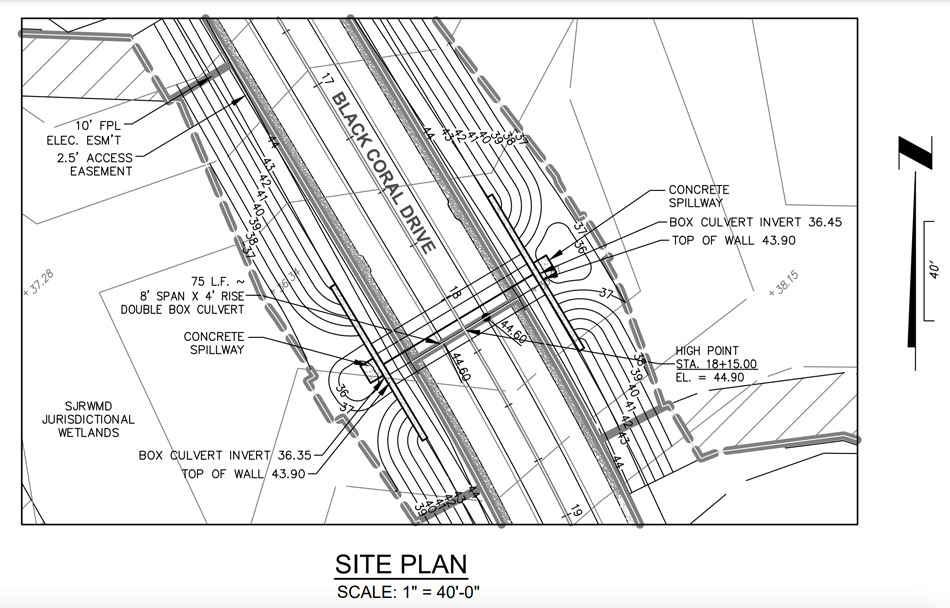

Project Name: Black Coral Drive Bridge Manufacturer: Truemont Materials Location: Coral Ridge at Nocatee, Florida Year Built: 2023

THE CHALLENGE

When the First Coast’s new developments need to maximize space, support infrastructure, or control water while prioritizing a beautiful, natural appearance, Redi-Rock precast large block retaining wall systems by Green Cove Springs’ own Truemont Materials are the perfect solution.

Nocatee’s Coral Ridge at Seabrook is a new master-planned community approximately 30 miles southeast of greater Jacksonville, offering 182 estate-sized homesites. The development features three distinct neighborhoods nestled among small lakes and wetlands. An early section of the development required bridging a significant stream to provide access to the phase’s 18 homesites.

THE SOLUTION

A roughly 73-ft (22.25 m) bridge was necessary to cross an active stream. The structure needed to meet several essential criteria. A fast and efficient installation process was necessary for timely access to the home sites. The bridge also needed to be stout enough to handle the considerable weight of large trucks and construction equipment when home construction got underway. Finally, the bridge’s finished appearance couldn’t be overlooked as it served as a de facto gateway to this particular phase of the development. With these needs in mind, a precast concrete box culvert bridge featuring several Redi-Rock block types was identified as the preferred solution for the project. Box culvert bridges are comprised of large open-ended precast concrete boxes. They’re supported with headwalls and wing walls built of large wet cast concrete blocks, like Truemont Materials' Redi-Rock.

THE PROJECT

Engineers across Florida are choosing box culvert bridges over alternatives like modular steel bridges, cast-in-place solutions, or corrugated metal pipes because box culvert bridges provide a better combination of installation speed, structural strength, and cost-effectiveness. Projects like the Black Coral Drive bridge project can reap significant value from each of these benefits. In the case of this project, a reliable bridge was necessary to access homesites that needed preparation and, ultimately, new home construction. Timely installation and the ability to handle big machinery were required. And no developer wants to spend more than they have to when investing in reliable infrastructure. However, the Black Coral Ridge Drive bridge was also tasked with a larger purpose – acting as a gateway to one of Coral Ridge at Seabrook’s early residential phases.

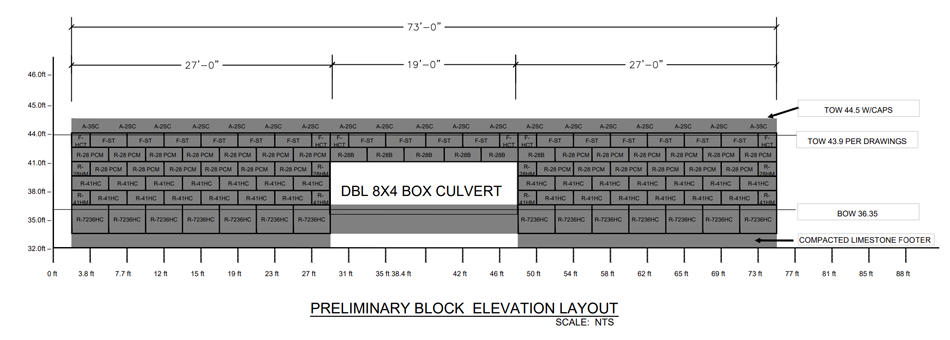

The project used double 8 ft x 4 ft (2.4 m x 1.2 m) box culverts as the bridging structure. Multiple Redi-Rock block types were used to construct the necessary headwalls and wing walls, which measured 11 ft (3.35 m), including 3 ft (0.91 m) buried below grade in most areas.

The headwalls and wing walls included a base course of fourteen 72-in (1830 mm) XL Hollow Core blocks. Two courses of 41-in (1030 mm) Hollow Core blocks followed, totaling 26 blocks. Twenty-five 28-in (710 mm) Positive Connection (PC) blocks were installed next. The final course consisted of sixteen 41-in (1030 mm) Top blocks. Several utility blocks were utilized in a limited fashion, including several 28-in (710 mm) Half Middles, 41-in (1030 mm) Half Middles, and Half Corner Tops. Two-Sided Caps were installed on top to give the wall a finished appearance.

THE OUTCOME

To ensure a refined yet natural appearance, developers selected Truemont’s popular Ledgestone texture. Ledgestone offers a highly detailed stacked stone look with deep, rich grooves. Striking columns and black iron fencing were added to each bridge end to further enhance the structure. The roadway and sidewalks in both directions were installed, reinforcing the development’s promise of walkability and a comfortable residential feel.

Products Featured

XL Hollow-Core Retaining Blocks – Hollow-core design helps build taller walls in tight spaces while using less concrete.

Gravity Retaining Wall Blocks – Massive, one-ton Redi-Rock gravity blocks rely on the sheer mass of each block to hold back the earth.

Positive Connection (PC) Wall Blocks – Build MSE retaining walls with the revolutionary Redi-Rock Positive Connection (PC) blocks.

Cap Blocks – Redi-Rock cap blocks are the perfect way to finish a retaining wall, freestanding wall, or column.

Ledgestone Texture – Ledgestone blocks give projects a random, stacked stone look.