Project Owner Manages Parking Lot Utilities with Gravity Wall

Project Name: Commonwealth Logistics Center Building 2 Owner: InLight Real Estate Partners Manufacturer: Truemont Materials Location: West Jacksonville, Florida Year Built: 2023

THE CHALLENGE

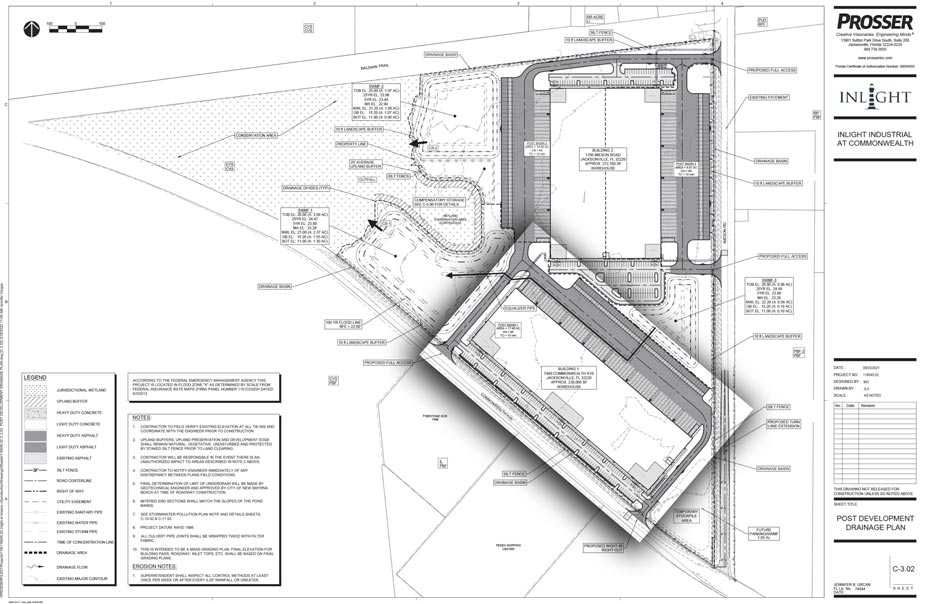

In 2023, InLight Real Estate Partners constructed a 229,840 sq ft (21352 sq m) multitenant logistics warehouse in West Jacksonville. The facility is a single-load warehouse with docks facing away from Commonwealth Avenue. Parking was needed on the Commonwealth Avenue side of the facility, with a relatively narrow strip of land available between the warehouse and the roadway. This area was elevated and leveled for the creation of employee and visitor parking. A retaining wall was needed to support the load of the parked vehicles but could not include any back-of-wall reinforcement like geogrid due to the necessary placement of drain utilities, including 30-in (762 mm) reinforced concrete pipe (RCP) and C Inlet precast boxes, behind the wall.

THE SOLUTION

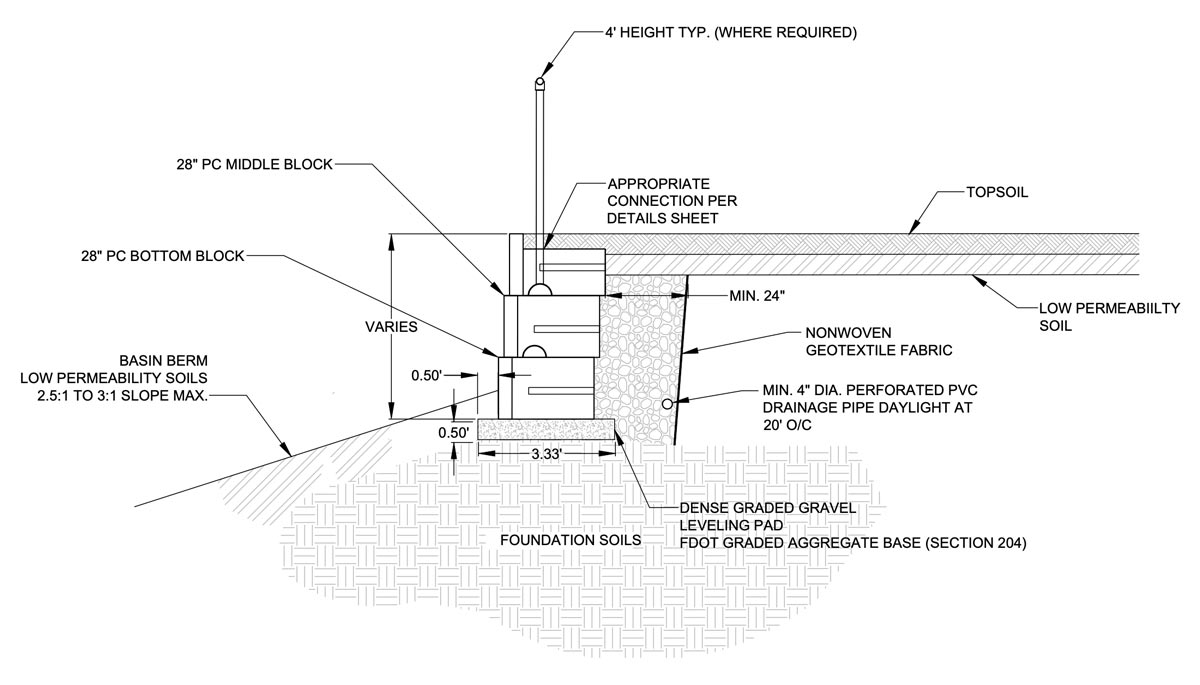

InLight selected a three-course Redi-Rock gravity wall, locally produced and supplied by Truemont Materials. Redi-Rock’s gravity solutions are a top choice for wall designers when significant earth or dynamic loads must be retained and installation footprints are tight. In the case of this project, the wall was tasked with supporting the possible combined weight of nearly 170 parked vehicles at any given time, requiring a traffic live load surcharge minimum of 150 psf (732.4 kgf/m²).

THE PROJECT

The Commonwealth Logistics Center Building 2 wall was composed of 41 in Hollow Core and 28 in Middle and Top blocks. Corner Garden Top blocks were installed at the ends of the walls allowing the contractor the flexibility of removing the back swale for a uniform look.

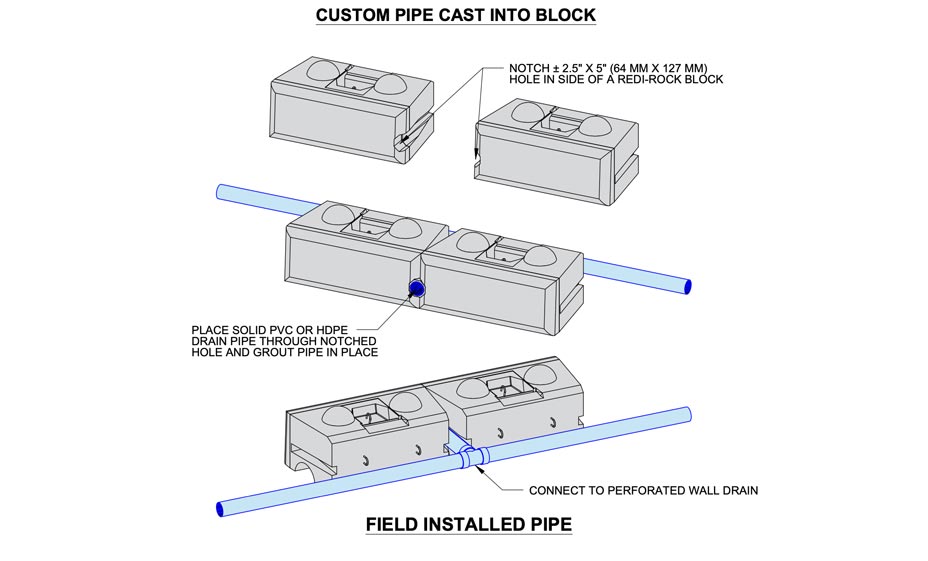

Surface drainage was achieved with C Inlets, draining to a run of reinforced concrete pipe present behind the wall. The needed drainage prevented the use of wall reinforcement like geogrid, making a gravity wall the only feasible option. The sides of 41 in (1030 mm) Hollow Core blocks were notched at intervals to host the placement of weep hole pipes so the pipe could fully drain to the ground below.

To enhance safety, fencing was installed atop the wall, securely fastened to the 28 in Top blocks.

THE OUTCOME

The completed Commonwealth Logistics Center Building 2 Redi-Rock gravity stretched an impressive 776 ft (236.5 m). It required 538 total blocks and totalled 3100 sq ft (288 sq m) in face area. Redi-Rock’s popular Ledgestone texture was selected for its random stacked stone appearance, mimicking the character of natural stone with its deep grooves and detailed face.

Products Featured

- Gravity Retaining Wall Blocks – Massive, one-ton Redi-Rock gravity blocks rely on the sheer mass of each block to hold back the earth.

- Limestone Texture – Redi-Rock Limestone blocks mimic the texture of natural split Limestone.